360 VR simulator

Prestart Heating of a Steam Turbine

How young hackathon participants became part of the VR development team for URALCHEM,

one of the largest chemical companies in the world

Cost

from 6 500 USD

2

MONTHS OF DEVELOPMENT

>1.5

MORE THAN 1.5 M RUB OF BUDGET-

SAVING

SAVING

75%

INCREASE IN INFORMATION

RETENTION

RETENTION

About the client

URALCHEM is one of the largest manufacturers of chemical products in the entire Commonwealth of Independent States. They are Russia's leading producer of ammonium nitrate and one of the largest domestic producers of ammonia, urea, and nitrogen fertilizers.

Background

URALCHEM and Varwin have worked together in the past. The Varwin team has developed several VR simulators for URALCHEM including:

Assembly / disassembly of X-45/54 pump

Flaw detection of X-45/54 pump parts

Dismantling of a KP401 compressor

Technological operations with X-45/54 pump

Pump starting, stopping, and handling for repair

The New Challenge

URALCHEM enlisted the help of Varwin to upgrade a Unity-based VR simulator developed by another contractor. The problem was that the project did not run until the end and was unstable from a technical point of view (the frame rate was about 15 FPS) and only a web version was available.

Specifications

Development framework:

Varwin XRMS

Varwin XRMS

Devices: Windows 10 PC, Oculus Quest 2 Mobile

The Solution and Work Stages

The Varwin team decided to rebuild the VR simulator in 360 format and outlined the following steps:

1

Project analysis

We unmade the project, revised the main objects and the script, and created the missing elements. Then the VR simulator was prepared for optimization.

2

Project optimization

The problem had been related to the frequency of frame changes per second. To correct and optimize this, we divided the overall scene into several different scenes. Then we added objects and elements and prepared the project to be exported to the Varwin XRMS platform.

3

Building on Varwin XRMS

The final stage was the exporting of the VR simulator to the Varwin XRMS platform. Our team built scene templates, configured the logic of object interactions, and tested it on Varwin XRMS.

What do the participants of the VR hackathon have to do with it?

In the autumn of 2020, Russia hosted the national Varwin Education Hackathon for grades 7 through 11. The event was called "The VR Developer: A Career for the Future." During the remote hackathon, 250 students from all over Russia, under the guidance of mentors, developed more than 80 full-fledged projects on the Varwin XRMS platform. These included:

chemical experiments that are dangerous to carry out in a real laboratory;

the Mendeleev's Table project where the main character collects chemical elements;

and a "Distance Learning" project with virtual Geography, Life Safety, Physical Education, English, and Physics classes.

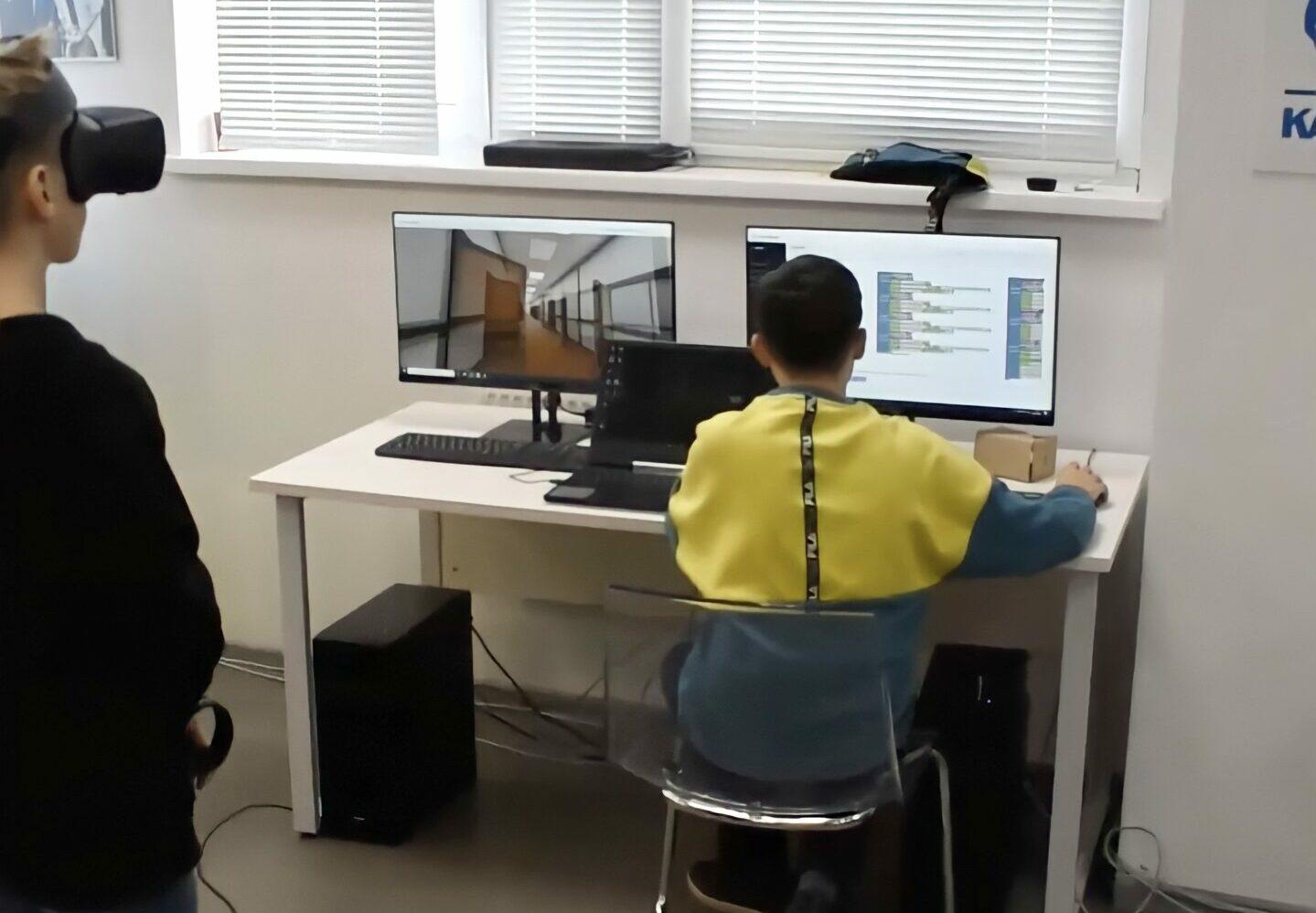

Photos of the VR hackathon participants

Our client, URALCHEM, had a representative at the event. They were a member of the jury evaluating the participants' results. As the hackathon progressed, we began discussing an amazing opportunity. The Varwin team offered the idea of involving the VR hackathon's young participants in a real-life project for URALCHEM. The students would be challenged to build ready-made templates that would simulate the heating of a steam turbine. Having seen the projects of the participants, URALCHEM agreed to their involvement. And under the guidance of our mentors, the "Prestart Heating of a Steam Turbine" 360 VR simulator project was created.

VR Hackathon participant feedback

360 VR Simulator

Prestart Heating of a Steam Turbine

Results Overview

Students were able to gain valuable educational experience working on a project for a real-world client. URALCHEM showed its social and educational support, and Varwin gained new users and fans of the Varwin XRMS platform.

Project results

The project was rebuilt and upgraded on the Varwin XRMS platform

The development time was reduced from 4 to 2 months

The frame rate was increased from 15 FPS up to 90 FPS

Together with URALCHEM, the Varwin team gained a social and educational case for building the project together with the participants of the hackathon

We cut the client's budget by 4 times

We gained new fans of the Varwin XRMS platform

Cost: from 6 500 USD

Customer feedback

Other cases

VR simulator for industrial safety training at the Magnitogorsk Metallurgical Plant

Varwin developed a VR simulator for training personnel in safety practices and violation detection. The Varwin team created 3D models of seven production site workshops. Each workshop contains replicated work areas that allow users to move around in VR.

3D & VR simulators for the Teplocom production and engineering company

Teplocom personnel can now simply and easily present and demonstrate their products at exhibitions and dealer meetings with the help of Varwin.

>

>