Largest oil company in CEE trains with VR

The VR opportunity for Gazprom Neft

Developing and operating petroleum sites means to manage a vast range of serious risks regarding the environment, employees, and the business itself. Gazprom Neft, one of the biggest gas and oil producers in CEE, requires training employees to operate complex equipment in hazardous environments where mistakes can have fatal consequences. Therefore, they approached Varwin to explore the opportunity to train new talents with a VR simulation and prepare them as good as possible.

The objectives

Our client had three main objectives, namely:

- Teach new employees to work with complex equipment,

- Test the knowledge of existing staff,

- Automate the evaluation process of training sequences.

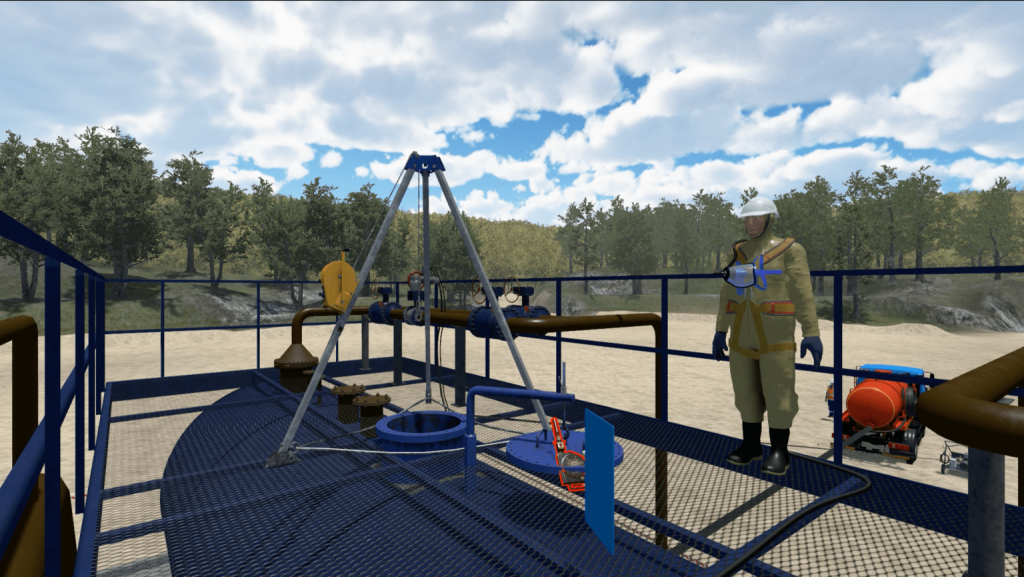

Gazprom Neft desired to start with the specific use case of getting rid of oil sludge. The treatment of oil sludge is a specifically hazardous process as a) the waste is an environmental risk and b) is harmful to the health of the employee removing it. Therefore, our developers and designers set out to create a sophisticated simulation to tackle this challenge.

The VR training

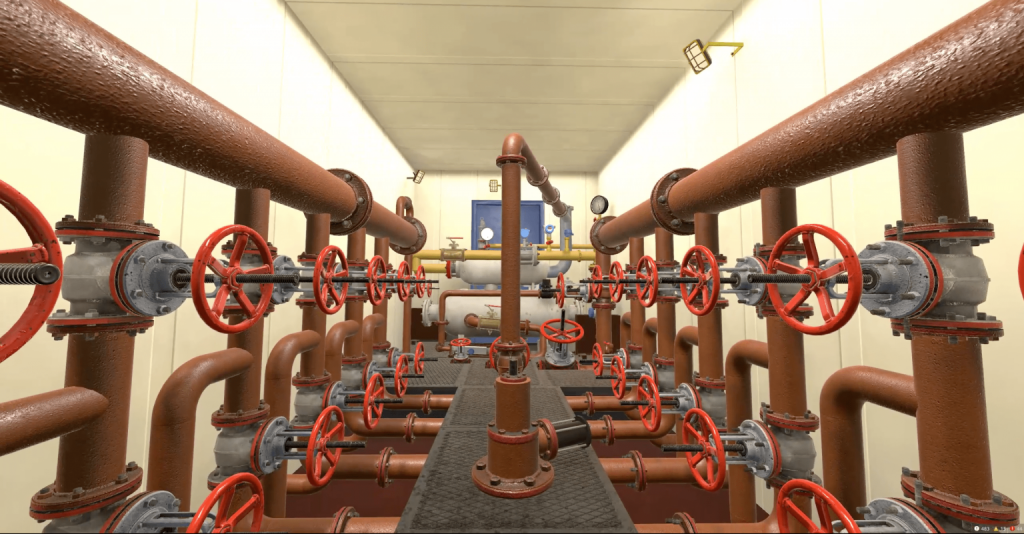

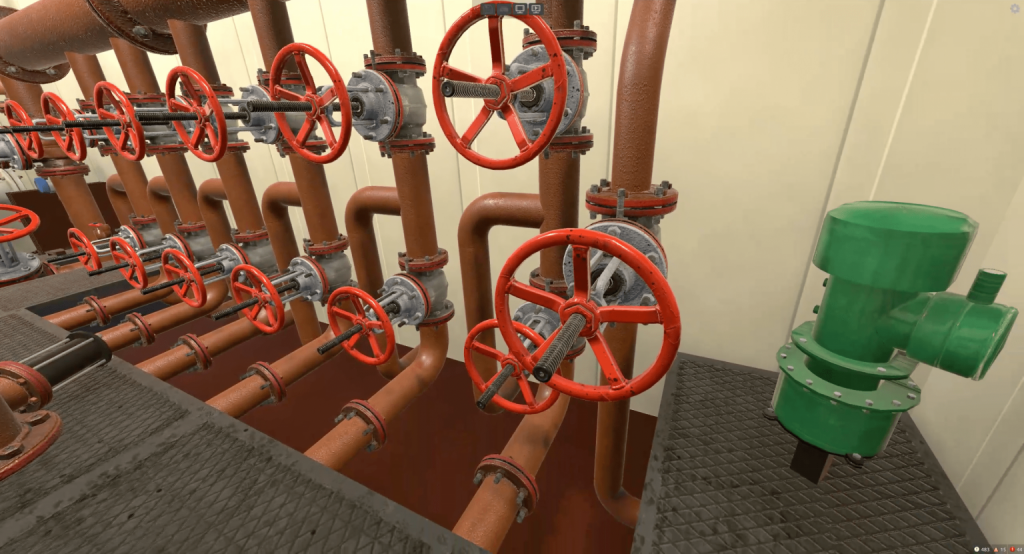

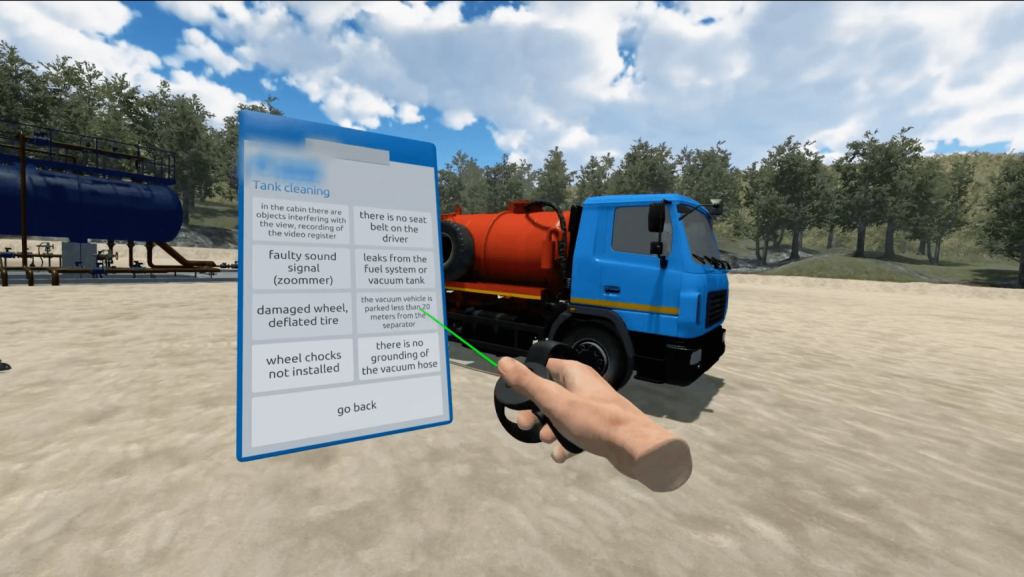

Our team created a simulation covering the entire process from checking the credentials of colleagues, inspecting the condition of the required equipment and eventually the sequential process required to change the valves as well as getting rid of the oil sludge.

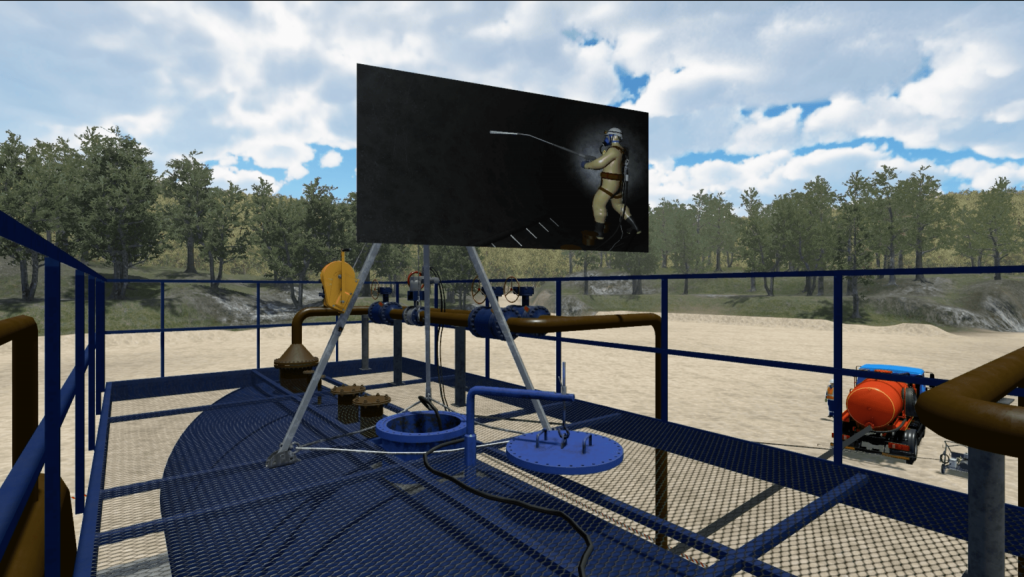

Varwin’s solution uses speech recognition to analyze the answers given by the participating employees. Moreover, we use motion analysis to determine how well a single step has been executed. This is specifically crucial as replacing a valve incorrectly may cause significant environmental damage once the pressure is back on.

Our developers have interviewed employees as well as risk managers to capture the details of the process and create a detailed simulation.

Our developers have interviewed employees as well as risk managers to capture the details of the process and create a detailed simulation.

Scoring the success of employees

The simulation represents all subtleties across the entire process. This enabled us to create a sophisticated evaluation system which rates mistakes based on their gravity as well as on the risk of creating a domino effect. In addition to our automatic evaluation system, a talent manager can monitor the entire process from his dashboard and recognize shortcomings for every employee individually. This enables our client to tailor the future training sessions to the specific requirements of the employee rather than offering general training only.

A flexible solution based on our proprietary platform

The equipment used in their operations changes constantly. That is why our client emphasized the importance of having a flexible and dynamic solution which allows them to update the existing VR simulation accordingly. Varwin’s proprietary low-code XRMS platform has been specifically developed to accommodate changing environments in the simulation. This enables Gazprom Neft to update the provided solution by themselves without the requirement to hire another developer.